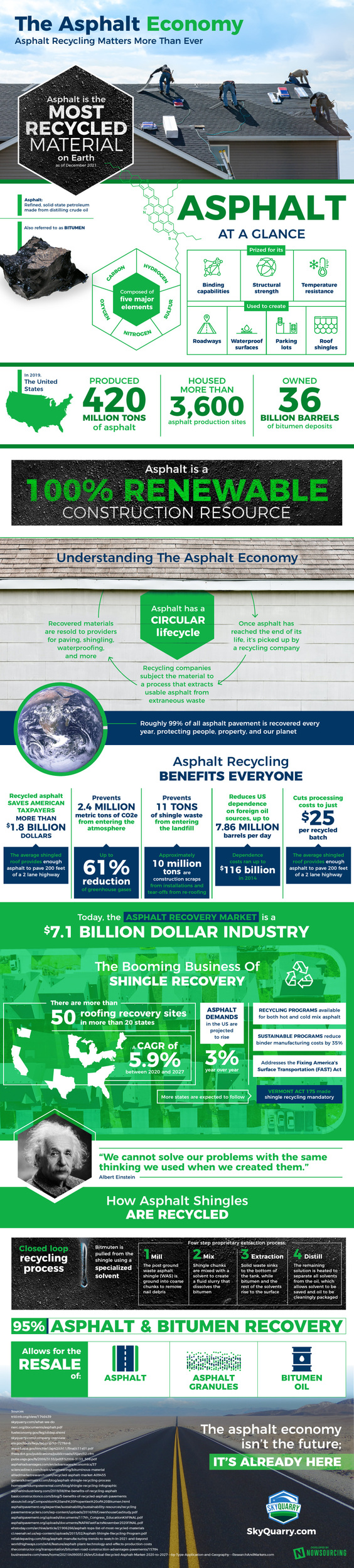

The Importance of Recycling to the Asphalt Economy

As of December 2021, asphalt is the most recycled material on Earth. This solid state petroleum product is made from distilling crude oil into the solid state. It may also be referred to as bitumen. As a petroleum product, its 5 main elements are organic in nature: carbon, hydrogen, oxygen, nitrogen, and sulfur. At a glance, asphalt is prized for its binding capabilities, structural strength, and resistance to extreme temperatures. Bitumen is a common construction material that is used to create roadways, parking lots, and roof shingles. While bitumen can be found naturally, it is more common for the material to be manufactured. The largest natural reserve of asphalt covers 140,000 square kilometers and can be found in Canada.

The US makes a lot of asphalt. In 2019, America produced 420 million tons of asphalt at over 3,600 production sites. In that year, the country owned 36 billion barrels of bitumen deposits. Production can be difficult, as vacuum distillation is required to separate asphalt from other crude oil components, namely gasoline and diesel. Asphalt produced new can have several negative impacts on the environment, but there is a silver lining to the situation. As mentioned above, asphalt is frequently recycled. In construction, asphalt is a 100% renewable construction resource. An entire economy exists around the use and reuse of asphalt.

How does asphalt recycling work? The cycle is fairly straightforward. Once asphalt has reached the end of its life, it is picked up by a recycling company. Recycling companies subject the material to a process that extracts usable asphalt from extraneous waste. In a closed loop recycling process, bitmuten is pulled from the shingle using a specialized solvent. There is a 4 step proprietary extraction process. First is milling, where post ground waste asphalt shingles are ground into coarse chunks to remove nail debris. Next is mixing, in which chunks are mixed with solvent to create a fluid slurry that dissolves the bitumen. Then comes extraction, where solid waste sinks to the bottom of the tank while bitumen and the rest of the solvents rise to the surface. Finally, distillation happens. The remaining solution is heated to separate all solvents from the oil, which lets the solvent be reused and oil be cleanly packaged. Following that process, recovered materials are resold to providers for paving, shingling, waterproofing, and more. Roughly 99% of all asphalt pavement is recovered every year, protecting people, property, and planet.

Asphalt recycling benefits everyone. Recycled asphalt saves American taxpayers more than $1.8 billion annually. Reusing petroleum products reduces US dependence on foreign oil, a sticky political issue that can run up to 7.86 million barrels per day. By recycling asphalt instead of always producing more, 2.4 million metric tons of carbon dioxide are prevented from entering the atmosphere. Sending shingle waste to a recycling company keeps 11 tons of shingle waste from clogging up the landfill. After all, approximately 10 million tons of shingle waste are construction scraps from installations or tear-offs from re-roofing. The average shingled roof provides enough asphalt to pave 200 feet of a 2 lane highway.

Today, the asphalt recovery market is an industry worth $7.1 billion. There are more than 50 roofing recovery sites in operation across 20 states. This industry is concentrated in the northern Midwest, but California, Texas, and portions of the South are also participating. More states are expected to follow suit. IN one state (Vermont), shingling recycling is mandatory. Recycling programs available today for both hot and cold mix asphalt. Sustainable programs are able to reduce binder manufacturing costs by 35%.

Source: InvestSkyQuarry.com